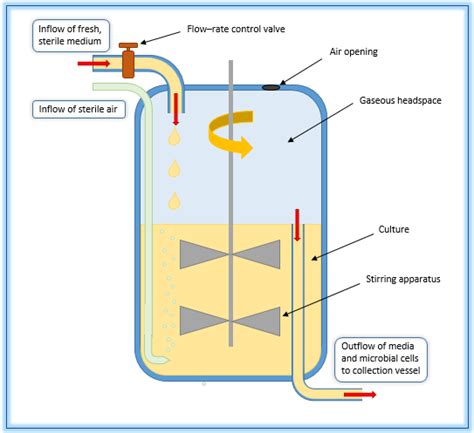

Fermenters play a crucial role in various industries, particularly in the field of biochemistry and brewing. They come in different types such as batch, fed-batch, and continuous cultures. The design, operation, and applications of fermenters are diverse and cater to specific needs. In biochemistry, fermenters are often used for the extraction of energy from carbohydrates in an oxygen-free environment, a process essential in many biochemical applications.

Professional-grade fermenters, often made from stainless steel, are designed for under-pressure fermentation and maturation. They are crucial in the beer brewing process, where after primary fermentation, the beer is transferred to another fermenter, leaving behind yeast sediment. This process highlights the importance of choosing the right fermenter for optimal brewing results. Stainless Steel Fermenter (ad)

For homebrewing enthusiasts and commercial breweries alike, the choice of fermenter is key to successful brewing. Options range from simple food-grade buckets with sealable lids to large-scale stainless steel vessels. Each type of fermenter offers unique features, whether it’s for small homebrew setups or for large-scale commercial operations. The adaptability of fermenters, such as converting fridges into fermentation chambers, further illustrates their versatility in brewing processes.

The fermenter’s design also influences the fermentation process, with aspects like headspace and venting playing crucial roles. For example, fermenters like the S F50, designed for larger batches, or the Keg King 30l Chubby, suitable for pressure fermenting, demonstrate the variety available for different brewing needs. The use of fermenters isn’t limited to brewing; they’re also employed in producing biofuels, biopharmaceuticals, and in the food and beverage industry, showcasing their wide-ranging applications.