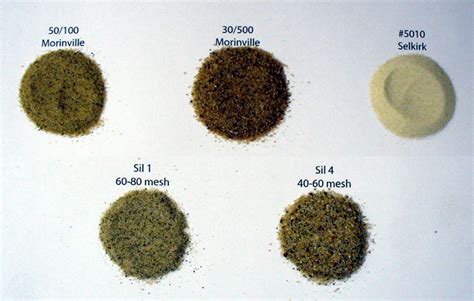

Cast iron, known for its durability and versatility, serves multiple purposes across various industries. A typical composition of a cast iron sand mixture includes silica sand, chromite sand, or zircon sand, ranging from 75 to 85%, sometimes combined with olivine, staurolite, or graphite. This mixture underlines the adaptability of cast iron, from the creation of robust cookware to the precision required in weightlifting equipment.

For the culinary enthusiasts, cast iron finds its way into kitchens via products like the Ooni Cast Iron Cookware, which is suitable for a range of cooking methods, from grilling to baking. In fitness, products like CAP Barbell’s 2-Inch Olympic Grip Plates, which come in various weights, are favored for their quality and even weight distribution provided by the solid cast iron core. The precision-ground plates utilized with lapping compounds ensure extremely flat surfaces for industrial purposes.

Architectural ironwork in cast iron is often preferred for restoration projects due to its traditional designs and lasting quality. Similarly, musical instruments benefit from cast iron’s strength, like the piano’s cast-iron plate, which holds the strings under high tension. The manufacturing process of gray and ductile iron through continuous casting results in a product that boasts improved machinability and consistency.

When it comes to material composition, cast iron’s carbon content ranges between 2–4%, along with other alloys, and 1–3% of silicon to enhance casting performance. The rubber coating on some weight plates protects both the barbell and the plates, adding to their appeal for lifters. Cast iron’s malleability is also noteworthy; gray cast iron, which is easier to cut than steel, can be shaped with standard tools, making it a versatile choice for various applications.